rough trading

Our long-standing partnerships with the world's premier diamond mining companies allow us to guarantee our clients a consistent and unparalleled supply of rough diamonds well into the future. We actively participate in all major tenders and auctions to maintain this advantage.

Our rough procurement and polished diamond divisions operate in continuous, transparent dialogue, enabling us to align our sourcing as closely as possible with our customers' evolving needs.

Based on our requirements for polished stones, we responsibly trade any rough that is not designated for our own manufacturing.

To preserve our high standards and reputation, we are extremely careful with the procurement of every rough diamond we purchase. All our diamonds are of conflict-free origin and are sourced from countries that participate in the Kimberley Process. We require our suppliers to provide only diamonds that have been procured through a conflict-free process and from sources that uphold our human-rights standards, ensuring integrity throughout our supply chain.

We maintain strong relationships with mining partners worldwide, ensuring consistent supply and ethical sourcing practices throughout our supply chain.

DIAMOND MANUFACTURING

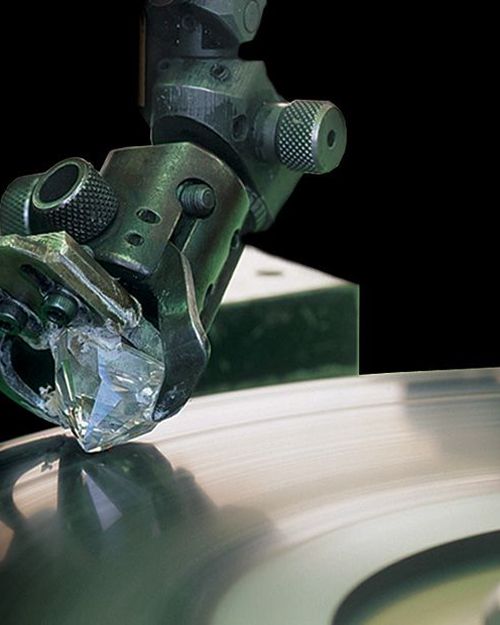

Our manufacturing centres across the world blend the heritage of master diamond craftsmanship with the most advanced polishing technologies and the highest technical standards.

We manage production through a rigorous system of internal controls designed to uphold quality and protect the integrity of our pipeline.

Every step involved in bringing a finished diamond to the end consumer is guided by transparent and responsible operating practices. We follow industry-standard due-diligence procedures to ensure ethical provenance and maintain strict oversight over our own processes. We participate in De Beers’ Pipeline Integrity (PI) programme, under which the process for ensuring that De Beers Forevermark diamonds originate from DTC is assessed and assured through defined procedural controls at certified operations. A small portion of our goods participate in blockchain-based traceability initiatives, and our core commitment remains consistent: strong internal controls, responsible sourcing practices, and vigilant measures across our in-house manufacturing to minimise the risk of undisclosed synthetics entering our supply chain.

Rosy Blue maintains a global network of advanced diamond manufacturing centres across India, Thailand, China and Botswana. Each facility blends skilled craftsmanship with modern technology to deliver exceptional precision. This diversified footprint enhances our agility and global responsiveness.

Our production ranges from rounds (from 0.005 pts to 10 cts+) to calibrated princess diamonds (from 0.03 pts to 10 cts+), as well as a wide variety of fancy shapes. Our manufacturing focuses on better-quality goods of SI quality or above. These are mainly round stones (0.005 points to 10 cts+), but we also produce princess diamonds (0.03 points to 10 cts+), and a range of round-edged fancy shapes. We handle AGS 000 stones, the hardest stones to cut, and GIA ‘Triple Excellent’ diamonds, as well as ‘Hearts and Arrows’ stones.

We also have proprietary, patented cuts, including the Cento: a 100-facet diamond that demands the most exceptional craftsmanship and expertise. We are always ready to discuss specific designs and ideas, and to develop new cuts to meet every requirement.

Full product list:

- Stars

- Full cuts

- Melees

- Pointers

- Caraters

- Larger specials

- Ideal cuts

- Certificate goods

- Princess cuts

- Round-edged fancies

- Colours and browns

“In today’s competitive and dynamic marketplace, customer satisfaction is crucial to securing a leading edge. Rosy Blue is committed to innovation and to delivering the best products and services, thereby improving people’s quality of life and contributing to a better global society.” – Mayank Mehta, Member Management Board

Rosy Blue is a business built around the needs of our customers. In fact, we have even adapted our manufacturing approach over the years to better serve the needs of our customers.

Rosy Blue adopts a value-driven approach to manufacturing: maximizing, at every stage, the value of the rough stone through superior makes and special cuts, offering speedier delivery, and defining more accurate projections of demand. From large programmes of fine makes to distinctive special cuts, our aim is always to deliver what the consumer needs, exactly when they need it.

“We need the diverse talents and full potential of every individual employee in order for Rosy Blue to excel as a leader in the global marketplace. Our diverse workforce is critical to exploring new ideas and creating innovation.” – Ravi Bhansali, Member of the Rosy Blue Brand Council.

We are continuously innovating, developing and investing in our manufacturing technology and processes to maintain our leadership position in the global diamond industry. Our current manufacturing technology includes:

- Lexus helium polishing, which is a highly accurate system for calculating and achieving the maximum possible value yield from a rough stone.

- Sahajanand laser cutting and polishing, which creates the pavilion and crown of the diamond.

- Dialits automatic blocking and polishing systems.

- Fantasy System and JD Edwards enterprise resource systems to manage our inventory.

We also have a global reputation as a pioneer in technological research and development, always looking for new ways to enhance output, efficiency, and excellence. For instance, we are currently in the process of finalising our own proprietary diamond colour technology.

POLISHED DIAMONDS

Rosy Blue is known worldwide as a market-maker in polished diamonds. By combining our own manufactured diamonds with polished stones sourced from the open market, we ensure a consistent depth of inventory, to meet the needs of many different clients.

"As partners to many of the world’s leading jewellery Brands and Retailers, we recognise the responsibility that comes with that trust. We rigorously uphold the integrity of our sourcing and production, ensuring every stone meets the highest standards. Our clients rely on us not only for exceptional products, but for personalised, value-driven support across their entire supply chain."

– Ravi Bhansali MD, Rosyblue NV

Our clients are a diverse group, ranging from the world's most prestigious international brands to large chain retailers catering to every price point, and small, speciality jewellers. As one of the world's largest diamantaires, we are one of the few companies that can consistently meet all these various needs.

The scale of our international manufacturing and procurement operations means we can offer a comprehensive range of high-quality polished diamonds. We are able to meet orders swiftly, efficiently, and to exceptionally high standards.

Our extensive range of polished diamonds includes:

- Stars

- Full cuts

- Melees

- Pointers

- Caraters

- Larger specials

- Ideal cuts

- Certificate goods

- Princess cuts

- Round-edged fancies

- Colours and browns

Our network of independent specialists work closely together to deliver exceptional service and quality to our clients worldwide.

Gemstones

Where Nature’s Colours Meet Human Mastery

Gemstones are stories shaped by the earth-each one formed through pressure, light and time into something uniquely expressive. At Rosy Blue, coloured stones are more than materials; they are living palettes that inspire design, craftsmanship and creativity across the world’s leading jewellery houses.

Our experts travel across continents to source stones that reflect integrity, personality and exceptional natural beauty. Every gem that enters our ecosystem undergoes a carefully designed journey-evaluated, sorted, cut and polished with precision to protect its character and unlock its full brilliance.

Heritage lapidary, modern engineering, flawless calibration

Rosy Blue’s coloured-stone capabilities bring together generations of lapidary tradition with advanced tools and cutting technologies.

Our centres in Thailand, India and Botswana are equipped to transform rough material into gems of remarkable symmetry, clarity and consistency.

Every stage-assorting, shaping, faceting, polishing and calibration-is guided by three principles:

- Respect the natural identity of the stone

- Enhance beauty through precise craftsmanship

- Ensure consistent output for global-scale manufacturing

This balance of artistry and precision is why international brands trust Rosy Blue to produce gemstones that perform beautifully both as centrepieces and in high-volume assortments.

A full spectrum of colour, shape and precision

Our collections span both calibrated stones and free-size premium pieces across a wide range of varieties, including:

- Emerald, ruby, sapphire

- Tanzanite, amethyst, citrine

- Peridot, garnet, topaz and more

We specialise in:

- Precision-calibrated stones for jewellery manufacturers

- Fine-grade centre stones selected for premium collections

- Fancy shapes & custom silhouettes engineered to design specifications

- Paired and layout stones for luxury jewellery

- Matched suites for high-value sets

Cutting options include ovals, rounds, pears, emerald cuts, cushions, trillions, princess cuts, step-cuts and mixed-cuts. We also partner closely with global clients to create exclusive, brand-specific gemstone cuts.

“At Rosy Blue, gemstones are a medium of expression. Each one carries a personality, and our role is to shape it into something that supports a designer’s vision.” - Viraj Mehta, MD Rosyblue HK

Our processes are built around the needs of premium and large-scale retail clients. We refine cutting angles, polishing techniques, batching and colour consistency so every stone in a collection supports the brand’s creative direction.

Our approach ensures:

- Maximum yield and brilliance

- Predictable supply for complex assortments

- Reliable colour and size uniformity

- Reduced lead times through optimised production

- Support for custom, design-led requirements

Whether a client needs thousands of calibrated stones or a handful of exceptional centre stones, we deliver precisely what the collection demands.

Where craftsmanship evolves with science

Excellence in coloured gemstones requires continuous evolution. Rosy Blue invests actively in research, equipment and digital systems to push lapidary performance forward.

Our technology stack includes:

- Automated colour and clarity grading for accuracy and reliability

- Laser-assisted shaping and cutting for precision and repeatability

- Advanced polishing systems that enhance lustre and saturation

- Calibration tools ensuring exact dimensional consistency

- ERP-driven digital inventory and traceability systems

We also pursue innovations in colour stability, material optimisation, and optical modelling-ensuring that Rosy Blue remains a benchmark in coloured-stone excellence.

Rosy Blue's gemstone division stands on a foundation of trust, technical sophistication and artistic sensitivity. With a global network, deep sourcing expertise and cutting facilities built on both tradition and innovation, we serve the needs of jewellery brands across more than 100 countries.

Every gem that leaves our workshops carries a promise:

Beauty, integrity and precision-crafted for the world's most remarkable jewellery.

JEWELLERY DESIGN & MANUFACTURING

Rosy Blue's jewellery division integrates design intelligence, manufacturing mastery, and robust global delivery - powered by the specialised strengths of Banas Jewels and Intergold.

Jewellery Design & Product Development

Rosy Blue’s design capability brings together global aesthetics, trend insight and precise engineering. Our in-house teams use advanced CAD/CAM modeling, rapid prototyping and structural simulation to transform creative concepts into production-ready designs

Whether for luxury collections or global retail assortments, we ensure every piece is optimised for beauty, durability and scalable manufacturing.

Jewellery Manufacturing Excellence

Through our specialised operations at Banas Jewels and Intergold, we deliver high-quality jewellery manufacturing at both artisanal and industrial scale.

Our capabilities span casting, assembly, precision stone-setting, micro-setting, polishing and finishing, executed by skilled craftspeople supported by modern machinery.

This integrated ecosystem enables us to produce complex fine-jewellery pieces as well as consistent, high-volume retail collections with reliability and precision.

Sourcing, Quality & Global Compliance

Backed by Rosy Blue’s global sourcing network, we hand-select diamonds and gemstones to meet exacting brand requirements for brilliance, calibration and consistency.

Every piece undergoes multi-stage quality control-from structural checks to finishing audits-ensuring adherence to global standards including RJC, BPP and international hallmarking norms.

This commitment to quality and compliance is why leading jewellery houses and retailers around the world trust Rosy Blue as a long-term manufacturing partner.